Process

Seyer Industries:

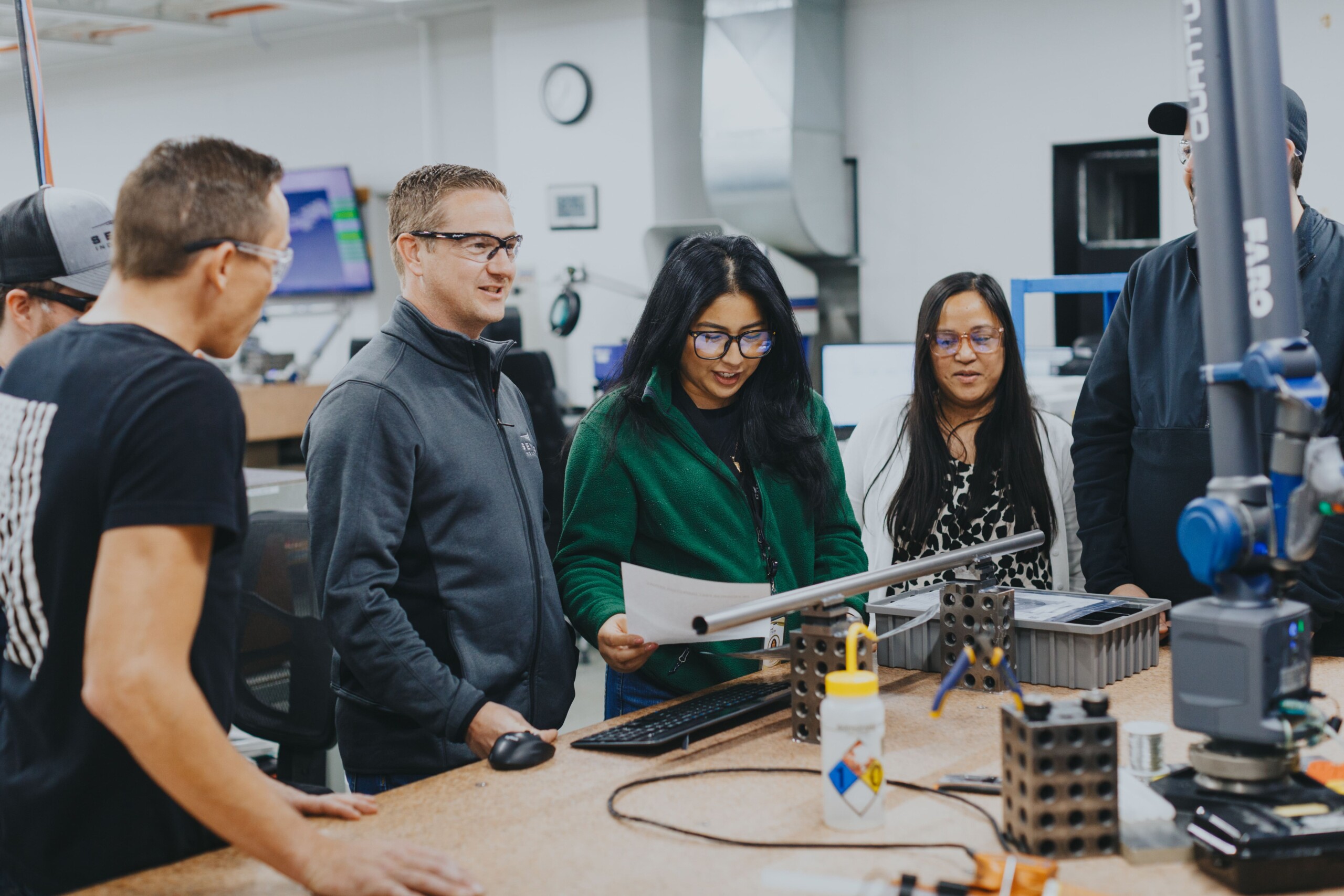

Customer Focused Continuous Improvement

ERP

Seyer Industries manages all business activities from quote to cash using Epicor Business Management software. Augmenting Epicor is a team of highly skilled software experts who transform data from Epicor, turning it into real time data for a total management solution.

Epicor provides for the following functions:

- Quote Development and Submittal

- Order Entry

- Bills of Material

- Manufacturing Planning

- Subcontract Signaling and Scheduling

- Production Scheduling

- Resource Management

- Real Time Performance Data

- Material Management

- Finance and Accounting

- Shipping / Delivery Management

Supply Chain Management

Seyer’s dedicated purchasing team is comprised of talented experts in the procurement field. The team uses proactive tools to manage procurement of all material and subcontract requirements per engineering defined bills of material. The team interfaces daily with project management and production control to manage schedules and cost to ensure delivery schedules are met.

- Organically developed “Advance Parts List” process to manage long lead and risk items coming from the supply base

- Commodity specialists for material, subcontract processing, standard hardware

- Establishing Strategic Relationships with key Suppliers

Project Management

Personalized customer support is a hallmark of Seyer Industries value proposition. We believe our customers deserve a steady “back and forth” accurate flow of information.

- Individuals from a pool of talented customer service personnel are assigned dedicated customer relations responsibilities for specific customers to manage the efforts below:

- Configuration management

- Engineering Change Activity

- In Process Status

- Delivery Forecasts

- Risk Management

- For strategic and key projects, an individual may be assigned solely to the project and given responsibility and authority to ensure customer success

MANUFACTURING ENGINEERING

Seyer Industries has built a cadre of highly skilled manufacturing engineering personnel. Our staff has over 130 years total combined experience.

Software Systems

- Catia

- Unigraphics

- Solidworks

- Key Creator

- Mastercam

- Vericut

- Optipath

Personnel

- Multiple highly skilled 5 axis programmers

- Dedicated optipath programming

- Multiple planners skilled in machine details and assembly efforts

- Dedicated Draftsmen

- Manufacturing Engineer on staff

Continuous Improvement

Continuous Improvement is a process embedded in Seyer culture. Our team of continuous improvement experts focus on new technology, process improvement, and vertical integration to ensure we offer best in class customer value.

Seyer Industries recently established a Research and Development (R&D) facility. The R&D facility provides several risk reduction opportunities.

- Machine program proofing

- Test new software targeted for efficiency improvements (run time reductions)

- Prove out new material holding concepts

- Provide hands on experience for talent development efforts

- Customer collaboration and accelerated lead times